- Double Stages High Vacuum Transformer Oil Purifier

- Vacuum Transformer Oil Purification Machine Mounted On Mobile Trailer

- Lube (Turbine/Hydraulic) Oil Purifier

- Single Stage Vacuum Transformer Oil Purifier

- Vacuum Dehydration Oil Purification System

- Insulating Oil Purifier

- Portable Oil Filter Machine

- Coalescing Type Oil Purifier

- Disc-type Centrifugal Oil Separator

- Diesel (Fuel) Oil Filtration System

- Oil Filter Press Machine

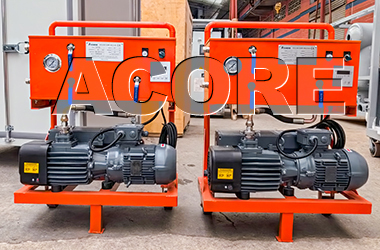

- Vacuum Pump Unit

- Air Drying Purification System

- Testing Equipments

- SF6 Gas Treatment Plant

- Accessories: oil filters, vacuum/roots pump, filtering tanks, oil pump, oil blender,etc

Acore Filtration Co. Ltd.

- Tel : +86 132 06063693

- Email : sales@acorefiltration.com

- Mobile & Whatsapp : +8613206063693

- Fax : +86 23 8132 4618

- Add : No.2, Jianhe Road, Banan District, Chongqing, China

Case

GER-100 SF6 Gas Filling and Vacuum Evaucation Machine Sales to Saudi Arabia

January 7,2026.

GER SF6 gas filling and vacuum evacuation machine

is an industrial device dedicated to vacuuming and filling sulfur hexafluoride

(SF6) gas in electrical equipment, with core functions including gas filling

and vacuum treatment, which is widely used in the maintenance of high-voltage

equipment such as circuit breakers, transformers and GIS.

Filling operation: Liquefaction storage gas (pressure 4.0MPa) through electric

heater, inflation rate 50-100m³/h, 1m³ equipment charging to 0.8MPa only 0.8

hours

Vacuum system: The rotary vane vacuum pump and roots pump achieves an ultimate

vacuum ≤ of 50Pa, a pumping speed of 25-1000m³/h, and is equipped with anti-oil

backflow protection to prevent pollution

Technical parameters and performance indicators of GER SF6 Gas Filling Machine:

Pumping rate: 25-200m³/h (regular model) or 100-1000m³/h (roots pump model).

Ultimate Vacuum Level: ≤5Pa (High Precision Type) or ≤20Pa (Standard Type).

Operating noise: ≤75dB(A), some portable models ≤ 70dB

Environmental Adaptability :

Temperature range: -10°C to 40°C, low-temperature models support -30°C

Power supply: customized, total power 1.1-18kW

Application and security specifications

Operation Process :

Vacuum extraction: After connecting the equipment, start the vacuum pump and

monitor the vacuum level to ≤133Pa

Inflating: Turn on the vaporization device, control the pressure ≤ 0.8MPa, and

avoid starting with pressure

The vacuum pump of SF6 gas filling machine is prohibited from reversing, the interface must be sealed to prevent leakage, and the built-in phase sequence protection is to prevent motor damage. Acore Filtration Company manufactures and sales two sets of GER100(100m3/h) vacuum pump machine for SF6 gas filling and vacuum evacuation processing.

+8613206063693

+8613206063693 Rufus Huang

Rufus Huang sales@acorefiltration.com

sales@acorefiltration.com +8613206063693

+8613206063693 +86 23 8132 4618

+86 23 8132 4618