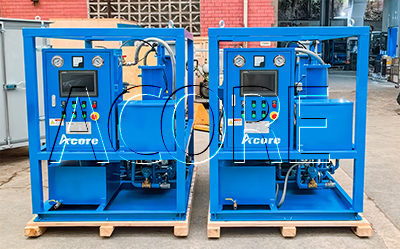

Acore Filtration Co.,Ltd sales two sets of DCS-30(3000L/H) centrifugal oil purifier to United Kingdom to purification of turbine oil in power generation. The core of Centrifugal Oil Separator can be summarized as the efficient and

continuous removal of solid contaminants (e.g., metal wear particles, dust) and

free water from lubricating oil through physical centrifugal force, thereby

significantly extending the service life of lubricant oil and protecting

expensive equipment.

Following is detailed breakdown for specific roles, working principles and

benefits:

1. Core role

Removal of solid contaminants (the most critical role)

Targets: extremely fine metal wear particles (iron, copper, aluminum, etc.),

dust, sand, sealing material debris, oil sludge and carbon deposits.

Importance: These hard particles are the "abrasives" of equipment and

can accelerate the wear of moving parts such as bearings, gears, cylinders,

etc., leading to reduced accuracy, reduced efficiency, and premature failure.

Centrifuges can remove particles as small as 1 micron or even smaller, which is

difficult to achieve with ordinary filters.

Target: Free water (water that can precipitate) and partially emulsified water

mixed in the oil due to condensation, leakage, or contamination.

Importance: Water can destroy the strength of the oil film, cause rust,

accelerate the oxidation and deterioration of the oil, and may breed

microorganisms to form oil sludge. Centrifuges can efficiently separate and

drain dense water.

By continuously removing contaminants, the cleanliness of the lubricating oil

(e.g. ISO 4406) can be stabilized at a very high level (e.g. ISO 14/12/10 or

higher) for a long time, which is a prerequisite for the reliable operation of

critical equipment such as hydraulic systems, turbines, compressors, etc.

Due to the continuous centrifugation of contaminants, the oxidation rate of the

oil is greatly reduced and the acid value increases slowly, thereby extending

the service life of the lubricating oil several times.

Working principle:

High speed rotation creates a strong centrifugal force: dirty oil is pumped

inside a rotor (bowl) that rotates at high speeds (usually thousands of

revolutions per minute).

Density stratification: Under the action of centrifugal force hundreds to

thousands of times greater than specific gravity, components of different

densities in the oil are rapidly stratified:

Outermost layer (densest): solid impurities (such as metal particles).

Mesosphere: Free water.

Innermost layer (least dense): clean lubricant.

Separation and Discharge:

The rotor of Centrifugal Oil Separator is designed with a special lamination

group or cylinder structure to guide and contain the separated contaminants.

Solid dirt adheres to the inner wall of the rotor, forming a strong sludge

layer that needs to be cleaned regularly by hand.

Free water (if present) is separated to a specific area and can be discharged

manually or automatically.

Clean oil flows out of the center of the rotor and returns to the tank or

directly to the equipment.

A simple analogy: Just like when a washing machine is spinning, the water (low

density) is thrown to the inner layer to drain away, and the clothes (high

density) are pressed against the walls of the bucket. The logic of centrifuges

handling oil is similar.

Summary

The role of Centrifugal Oil Purifier is essentially "preventive

maintenance of oil". It actively and continuously "throws" the

wear particles and moisture that are most harmful to the equipment out of the

oil through a powerful centrifugal force, rather than passively waiting for the

filter to clog. This not only protects the equipment and reduces downtime, but

also reduces the overall lifecycle maintenance costs of the equipment by

significantly extending the life of the oil and filter elements, making it an

efficient, environmentally friendly and economical solution for oil

purification.

+8613206063693

+8613206063693 Rufus Huang

Rufus Huang sales@acorefiltration.com

sales@acorefiltration.com +8613206063693

+8613206063693 +86 23 8132 4618

+86 23 8132 4618