- Double Stages High Vacuum Transformer Oil Purifier

- Vacuum Transformer Oil Purification Machine Mounted On Mobile Trailer

- Lube (Turbine/Hydraulic) Oil Purifier

- Single Stage Vacuum Transformer Oil Purifier

- Vacuum Dehydration Oil Purification System

- Insulating Oil Purifier

- Portable Oil Filter Machine

- Coalescing Type Oil Purifier

- Disc-type Centrifugal Oil Separator

- Diesel (Fuel) Oil Filtration System

- Oil Filter Press Machine

- Vacuum Pump Unit

- Air Drying Purification System

- Testing Equipments

- SF6 Gas Treatment Plant

- Accessories: oil filters, vacuum/roots pump, filtering tanks, oil pump, oil blender,etc

Acore Filtration Co. Ltd.

- Tel : +86 132 06063693

- Email : sales@acorefiltration.com

- Mobile & Whatsapp : +8613206063693

- Fax : +86 23 8132 4618

- Add : No.2, Jianhe Road, Banan District, Chongqing, China

Case

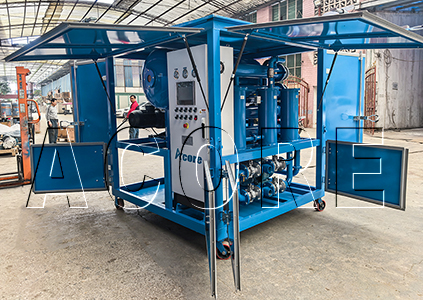

DVTP300 Transformer Oil Purification System Sales to Belarus

June 26,2025.

DVTP300(18000Liters

per hour) double stages high vacuum Transformer

Oil Purification System manufactured by Acore Filtration Co.,Ltd and

sales to Belarus. Belarus is carrying out the renewal of aging power facilities

from the Soviet era, especially the overhaul and maintenance of large

transformers. The Transformer Oil Purification System is used as a key

auxiliary equipment for on-site processing of insulating oil:

DVTP300 Transformer Oil Filtration Plant adopts two-stage vacuum technology which can efficiently remove water, gas and impurities from the oil, improve the dielectric strength, and ensure the safe operation of the transformer. The Transformer Oil Dehydration Machine can extend the life of the equipment by reducing the corrosion of metal parts due to oil aging, reduce dielectric loss, and avoid transformer failure caused by oil deterioration.

DVTP300 Transformer Oil Filtration Plant adopts two-stage vacuum technology which can efficiently remove water, gas and impurities from the oil, improve the dielectric strength, and ensure the safe operation of the transformer. The Transformer Oil Dehydration Machine can extend the life of the equipment by reducing the corrosion of metal parts due to oil aging, reduce dielectric loss, and avoid transformer failure caused by oil deterioration.

In order to adapt to the demand for renewable energy to be integrated into the

grid (e.g. photovoltaics, wind power), Belarus needs to upgrade its

transmission and distribution system:

Transformer operation and maintenance guarantee: The transformer of the new

energy power station needs regular oil filtration maintenance, and the Transformer Oil Filtration Plant can quickly

restore the oil quality and meet the requirements of grid-connected stability.

New equipment commissioning support: During transformer installation or

replacement, the Transformer Oil Purification System is used for vacuum oil

filling and drying treatment, which meets the stringent standards of

high-voltage equipment.

In order to promote the import of technical equipment, Belarus has introduced a

duty-free policy. From 2024, the import of designated technical equipment including Transformer Oil Dehydration Machine can be exempted from VAT, but it needs

to be put into use and complete the accounting of fixed assets within 6 months

after import.

Certification requirements: To enter the Belarusian market, it is necessary to

comply with local technical standards or CE certification, and DVTP Transformer

Oil Purification System oil products have passed the relevant certification, such

as CE certification.

The core application scenarios of Transformer Oil Dehydration Machine in Belarus include transformer maintenance in the transformation of traditional power grids, oil quality management of new energy supporting equipment, and benefit from policy support to reduce import costs. In the future, with the deepening of cooperation projects such as the China-Belarus Industrial Park, the demand for localized high-efficiency Transformer Oil Purification System is likely to grow further.

+8613206063693

+8613206063693 Rufus Huang

Rufus Huang sales@acorefiltration.com

sales@acorefiltration.com +8613206063693

+8613206063693 +86 23 8132 4618

+86 23 8132 4618